RAM ASD designs and manufactures a full line of multifunctional solenoid valves that can be used in a variety of aircraft and aerospace applications. RAM’s solenoid valves can be tailored to meet the most demanding applications, from high-temperature engine bleed air to fast-acting high-pressure hydraulic valves. Solenoid valves currently represent the fastest-growing segment of our business. RAM’s solenoid valve capabilities include the following:

Solenoid Valves

- Skydrol 500B-4

- Hydraulic MIL-PRF-5606

- Hydraulic MIL-PRF-83282

- Jet Fuel MIL-C-7024

- Air

- Nitrogen

- Helium

- Hydrazine

- Xenon

- Argon

- Specials

Solenoid Valve Types Include:

- Two way and three way

- Pilot Operated

- In line

- Spool

- Cartridge

- Co-axial

- Proportional

- Latching

- Position

- Butterfly

- 2 to 4 coil redundancy

- Latching, magnetic or mechanical

- Over-molded coils

- Rubber molded poppets

Check & Relief Valves

RAM’s Check and Relief Valves are manufactured from precision ground-heat treated components, withstanding operational pressures up to 5000 psig. These types of mechanical valves are utilized in systems for flow restriction, pressure control, and pressure relief.

Pressure relief valves offer many design features, including the following:

- Operating pressures from 0 to 5000 psig

- Cracking pressures from 20 to 4500 psid

- Low leakage

- Flow rates up to 18 gpm

Check valves design features include:

- Operating pressures from 0 to 5000 psig

- Low cracking pressures

- Zero leakage

Linear Solenoids

RAM’s linear solenoids encompass a vast array of design features and design applications, with strokes ranging from .005″ to 3″, push or pull performance, and pressurized or non-pressurized cavities. We are confident in meeting any reasonable performance requirement, including those related to the following:

- Magnetic or mechanical latching

- Positional devices

- Fast response time

- Redundant coils

- Manual override

- Long life

- Low power consumption

- Harsh environmental conditions

- Extreme vibration and shock

- Operation in a vacuum

- Extreme force requirements

- PWM capabilities

Rotary Solenoids

RAM’s rotary solenoids are pure rotary devices utilizing the angles of a balanced armature within a magnetic field. By eliminating cams or races that convert linear motion into rotary (common in rotary solenoids) we can offer distinct design advantages:

- Capable of 100 million cycles

- Fast response times

- Controlled torque curves

- High Reliability

- Magnetic latching in one or both directions

- Proportional capabilities

- No linear shaft motion

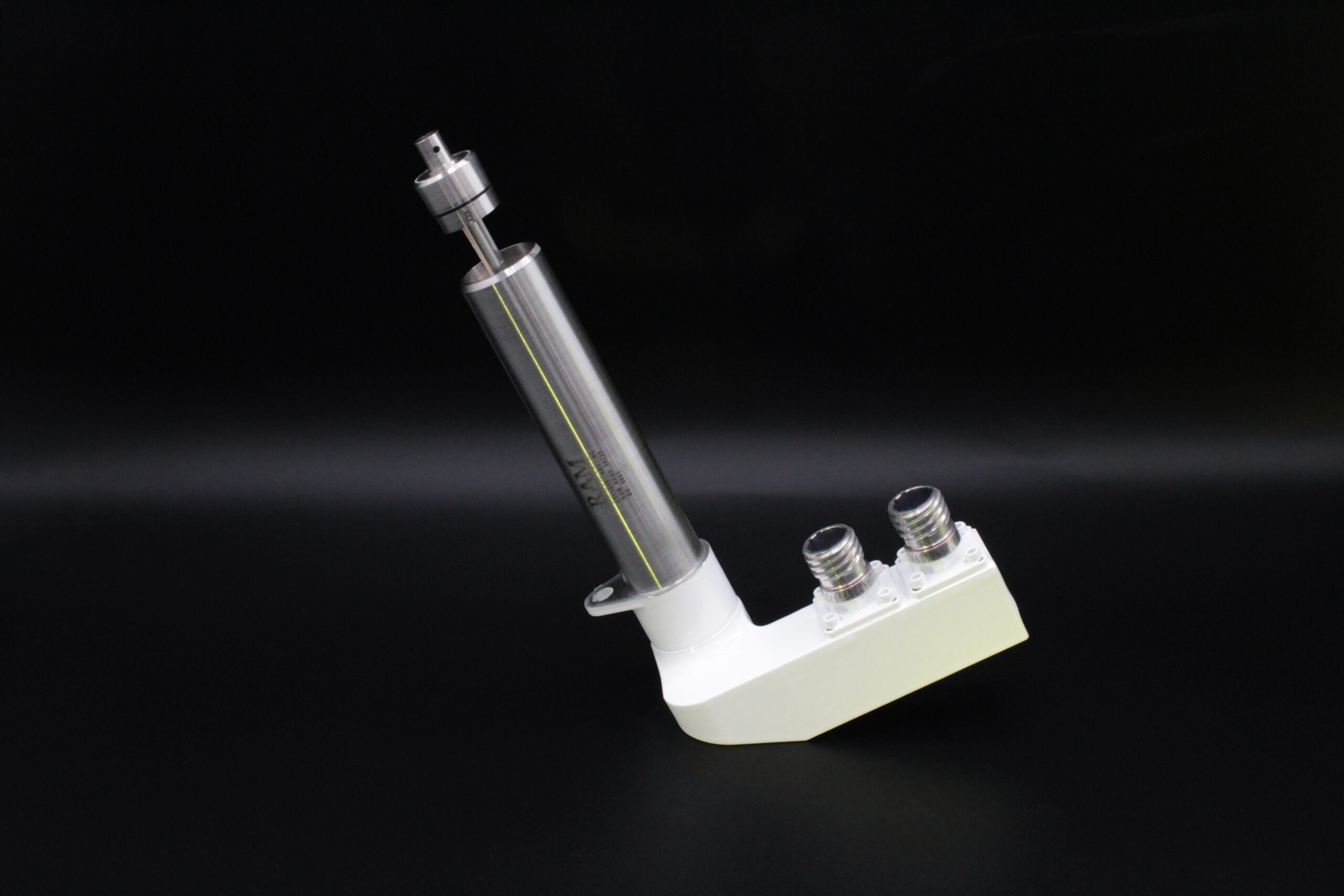

Linear Variable Differential Transformers

The Linear Variable Differential Transformer (LVDT) is an electromechanical transducer that converts the linear motion of an object into a precise electrical signal. This allows for accurate measurements to be made in mechanical systems before, during, and after motion occurs. RAM ASD is proud to add this product to our offerings with 5 different designs available.

Contract Manufacturing

Already have a solenoid or valve design? Following the successful formula used to build industry respect as a leading design and manufacturer, RAM Company additionally offers contract manufacturing to our expanding customer base.

Our modern facility has available capacity for build to print orders ranging from small batch to high quantity builds where dedicated production lines are required. Minimize your outsourcing costs by partnering with RAM to meet your strict technical requirements, on time, at an affordable cost.